What is a Rotary Actuator? What is its Function in Robot Joints?

A rotary actuator is an electromechanical (or fluid-powered) device that converts stored energy into a controlled angular displacement. In robot joints, it supplies the commanded torque, speed and position feedback that swing a link to an exact angle - typically within a few milliradians - so the arm can grip, weld, screw or inspect with repeatable accuracy. Brushless servo versions dominate modern robots because they pair high torque density with long, maintenance-free life.

What are the Selection Criteria (Torque, Speed, Resolution, Backlash) for Rotary Actuators?

Choosing an actuator means balancing four key performance metrics against the task.

- Torque : Must exceed peak load and inertia by ~30 % to avoid stalling.

- Speed : Ated RPM must meet cycle-time targets without overheating.

- Resolution: Smallest Commandable Angle (step size or encoder count) dictates positioning granularity.

- Backlash : Mechanical play on reversal; aim for <1 arc-min in high-precision assembly, higher values acceptable for coarse motions.

How do Different Rotary Actuator Types (Stepper, Servo, Magnetostrictive) Work?

Each technology follows a distinct physical principle to create rotary motion.

- Servo: Brushless motor plus encoder; a closed loop corrects current every microsecond for smooth, continuous rotation, high torque density and sub-degree accuracy.

- Magnetostrictive : Smart alloy twists in a magnetic field; that strain is amplified through a flexure, giving backlash-free, frictionless rotation with micro-second response.

- Stepper: Stator phases fire in sequence; every pulse moves the rotor one fixed step (e.g., 1.8 °), enabling open-loop, self-locking positioning.

Why engineering teams choose Norck actuators

- End-to-end manufacturing : We machine, finish, and assemble finished products in our clean room, which translates into a high level of quality.

- Built for extreme environments : Our electric rotary actuator can withstand high loads, harsh media, and heavy duty cycles.

- Seamless integration : We provide custom mounting solutions, torque and sensor configurations for any system.

- Engineered for control : If you have an application that requires a pneumatic rotary actuator with precise movements and positioning, we can help.

- Test and perform : Every Norck rotary actuator is lifecycle and stress-tested to limit your unplanned downtime.

- Designed for sustainability : Every step in our build process is efficient and we use environmentally friendly packaging.

- Worldwide support : Regional engineering assistance and fast parts availability to keep systems running without delays.

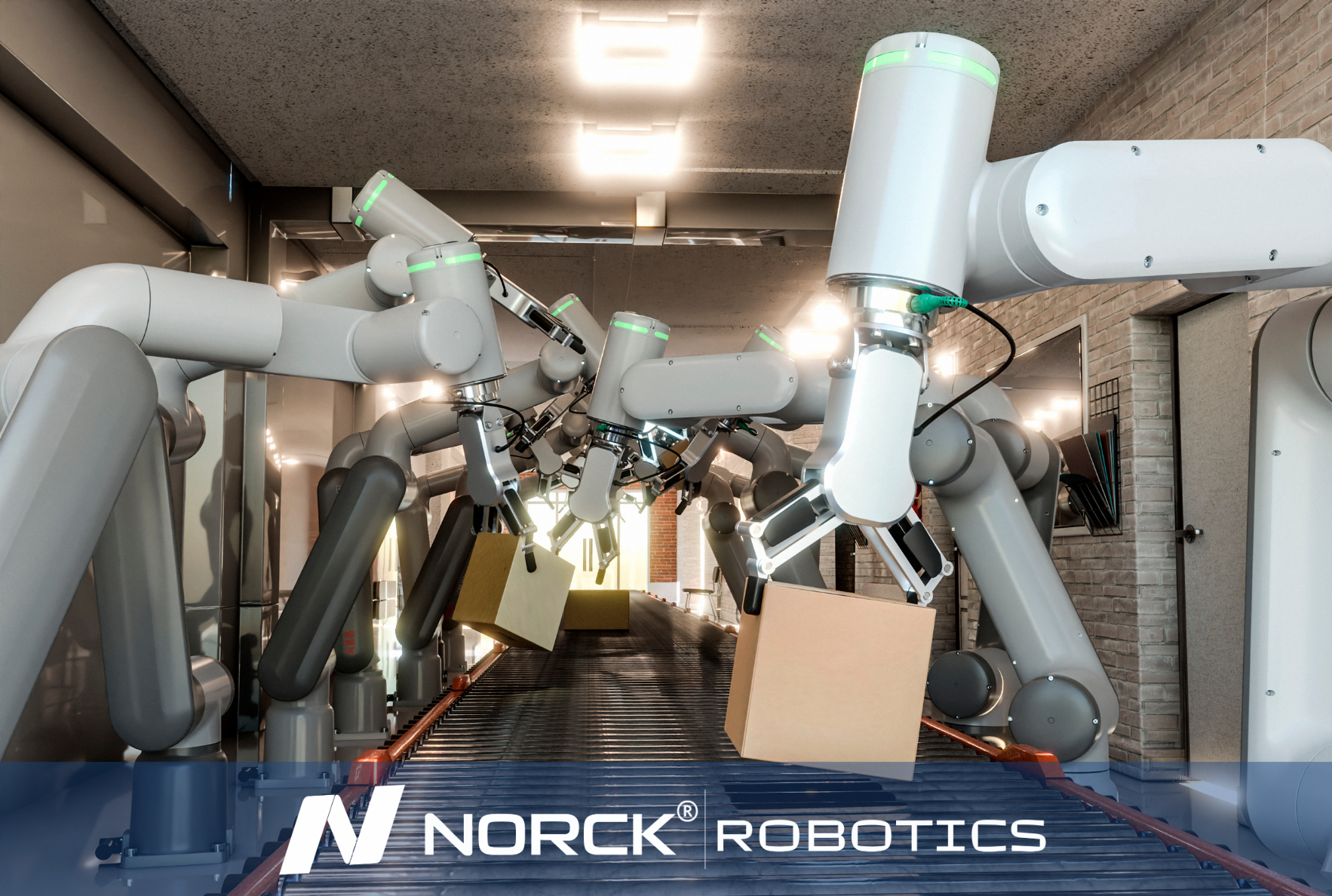

What Rotary Actuator Solutions does Norck Robotics Offer?

Nork Robotics has a comprehensive range of rotary actuator technologies that meet the specific and exacting requirements of today's automations and robotic systems. Norck provides actuators that merge reliability and performance where high-speed movement or positional accuracy is of prime importance.

- High-torque rotary actuator technology for rotating application with high torque ensures smooth motion under load and consistent output characteristics over cycles.

- Compact Servo Rotary Actuators fit well in confined spaces equipped with closed-loop control, fast response, and high accuracy for robotic joints and positioning tasks.

- Zero-Backlash Direct-Drive Actuators are constructed for ultra-precise motion; these actuators have no mechanical play, making them suitable for semiconductor, optical, and test automation systems.

- Scalable Custom Solutions are developed by Norck to arrive at custom-made rotary actuators matching exact mechanical, electrical, and environmental requirements thus ensuring seamless integration into specialized applications.

Robotic motion demands drives that balance precision, torque, size, and durability; thefive rotary-actuator families below each solve that puzzle in a different way.

- Brushless Servo Rotary Actuator: Couples a high-torque brushless DC motor with an integrated encoder, delivering smooth, closed-loop rotation, flat torque curves, and >90 % efficiency; its compact, sealed housing thrives in robot joints and 24/7 automation where millisecond response, low heat, and maintenance-free longevity are essential.

- Closed-Loop Stepper Rotary Actuator: Adds an encoder to a cost-effective stepper, so the controller corrects every micro-step in real time - eliminating missed steps, boosting torque at speed, cutting motor heat, and giving servo-like accuracy for conveyors, light-duty robots, and tooling that can’t justify full servo prices.

- Miniature Servo Gearmotor (PWM): Integrates a palm-sized servo, reduction gearbox, and feedback electronics; accepts hobby-standard PWM signals from Arduino/Raspberry Pi, delivers high torque-to-weight and sub-degree positioning, making it perfect for battery-powered rovers, STEM kits, and compact pan-tilt mechanisms.

- Magnetostrictive Rotary Actuator: Uses smart alloys that twist in a magnetic field, producing friction-less motion and contact-free position sensing; the resulting zero-wear design excels in harsh, high-vibration, temperature-swing environments such as heavy machinery, aerospace surfaces, and oil-and-gas valves.

- Precision Harmonic Drive Rotary Actuator: Employs an elliptical wave generator, flexspline, and circular spline to achieve zero backlash, high gear reduction, and stellar repeatability; the light, slim package supplies camera gimbals, surgical wrists, and micro-assembly robots with rock-steady, vibration-free positioning even under large torques.