What are the benefits of a brushless design in a servo motor?

By replacing mechanical brushes with electronic commutation, brushless servos eliminate friction and arcing at the rotor, dramatically reducing wear and extending service intervals. Efficiencies often exceed 90 percent, so more of your input power becomes usable torque rather than heat. The compact, integrated permanent-magnet rotor yields high torque density, allowing a smaller package to produce the same output as a larger brushed motor. With no brushes to generate electrical noise, control loops enjoy cleaner feedback signals, improving motion smoothness and repeatability.

How does the servo system achieve precise positioning and speed control?

At its core lies a closed-loop feedback architecture: a high-resolution encoder (10- to 20-bit or better) or resolver continually reports actual shaft angle and rotational velocity. A PID controller compares that real-time data against the commanded trajectory, instantly adjusting the motor’s phase currents to correct any deviation.

- Positioning: Sub-degree (often <0.01°) accuracy is possible by tuning proportional, integral and derivative gains to balance responsiveness and overshoot.

- Speed control: The system regulates motor torque to maintain a set rpm, compensating for load changes without hunting or sag.

- Acceleration management: Ramp profiles (S-curves) prevent jerks, safeguarding mechanical couplings and preserving part alignment during starts and stops.

For what applications is a brushless servo rotary actuator ideal?

Brushless servos bring their long life, precise control and compact form to a wide array of demanding tasks:

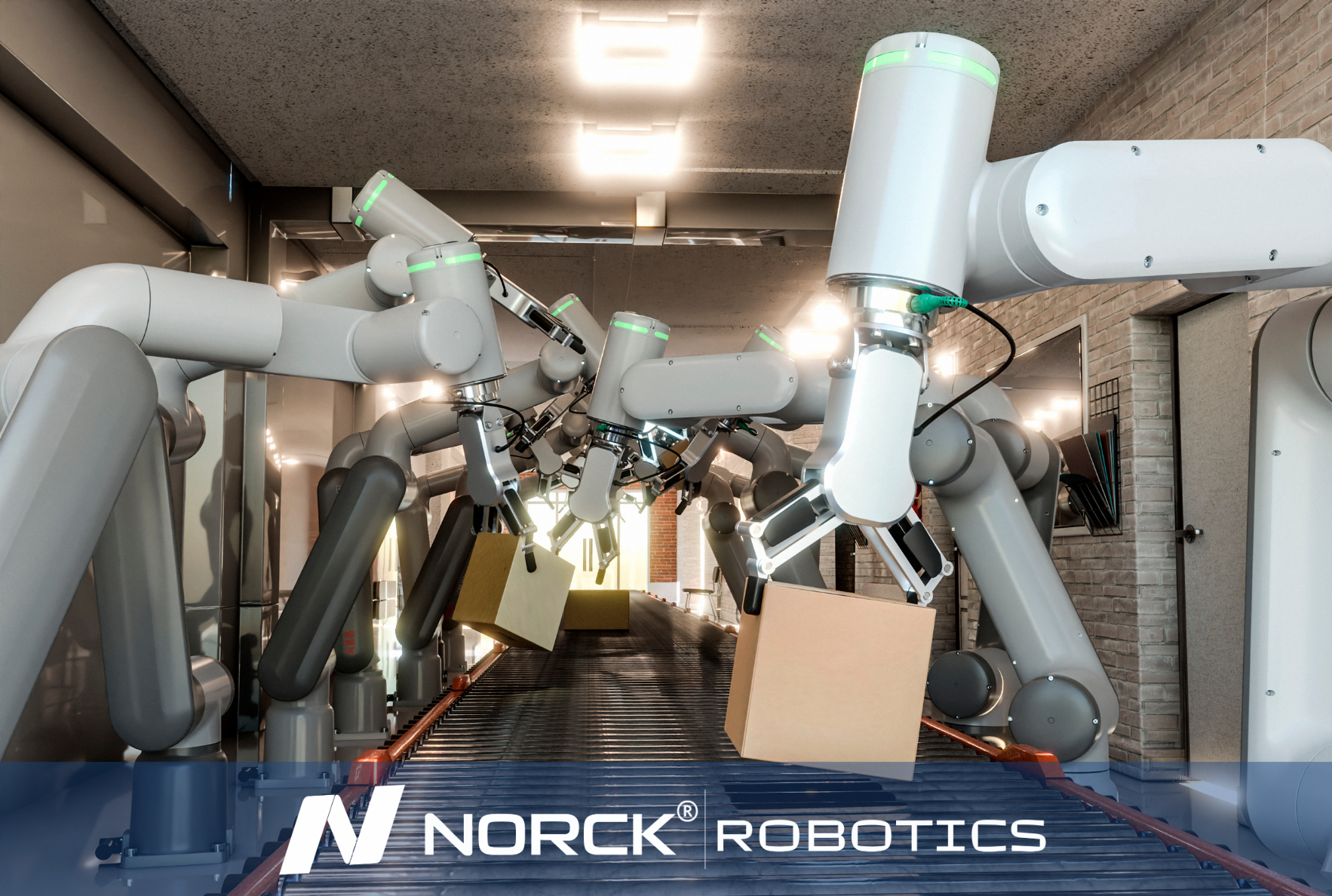

- Articulated robots & cobots: Smooth, jitter-free joint motion enables high-speed pick-and-place, precise weld paths and safe human collaboration with force-limiting capability.

- CNC & machining centers: Indexers and rotary tables demand sub-arc-second repeatability and rapid spindle orientation changes for complex multi-axis cutting.

- Automated guided vehicles (AGVs): Wheel and steering drives benefit from high torque-to-weight ratios and minimal battery drain for extended duty cycles.

- Medical & laboratory systems: From surgical manipulators to pipetting robots, quiet, low-EMI operation preserves delicate electronics and sensitive samples.

- Aerospace & defense gimbals: Tracking sensors or weapon mounts must survive vibration, temperature swings and still deliver micro-step accuracy.

- Imaging & inspection: Pan-tilt heads for cameras, lasers or structured-light scanners rely on smooth, backlash-free rotation to avoid artifacts in critical measurements.

In each case, the combination of brushless reliability, closed-loop precision and compact efficiency makes these actuators the go-to choice for modern motion control challenges.

Why is high efficiency important in rotary actuators?

Efficient energy conversion means less heat generation, which reduces the need for bulky heatsinks or active cooling and lowers bearing and lubricant breakdown rates. In 24/7 production lines or battery-powered AGVs, minimizing power draw directly cuts operating costs and extends runtime. Higher efficiency also lets you pair the motor with a smaller drive electronics package and power supply, saving panel space and simplifying system integration. Finally, reduced thermal strain preserves magnet strength and winding insulation, prolonging overall actuator lifespan.